Advantages of the flex arm Mount

With the Flex Arm Mount, the camera is installed on a ball-joint arm at the front, allowing it to extend further into the workspace. The Flex Arm can be integrated into the sheet metal wall, mounted in front of the wall, or simply fixed in place with a magnet for maximum flexibility.

Because the Flex Arm can be tilted by ±20° and rotated 360° at each of its joints, it’s even easier to adjust the camera to the optimal perspective. The arm also helps reduce the distance to the observed process.

- Tip: With additional joints in the Flex Arm Mount, the camera can be positioned even more freely in the workspace and placed closer to the machining process. An optional protective hose ensures that all supply lines are optimally protected in the working area.

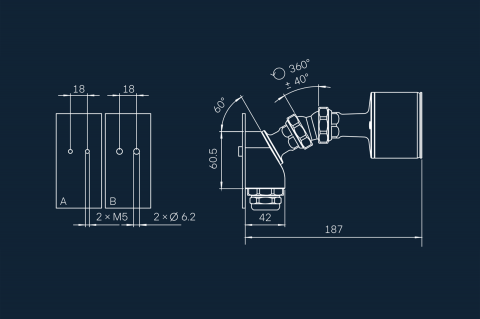

Through-wall mounting

For through-wall mounting, a hole is drilled in the sheet metal wall and the flex arm mount is screwed directly to it. This allows both the data cable and the sealing air hose to be routed outside the workspace.

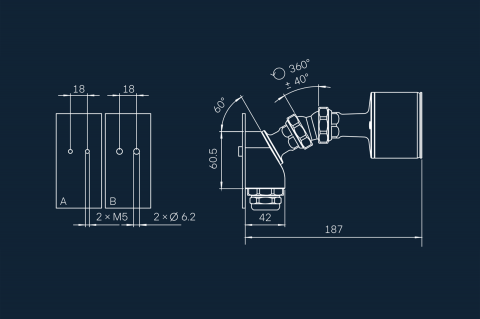

Pre-Wall Mounting

In pre-wall mounting, the Flex Arm Mount is fixed on a base in front of the wall inside the machine. In this case, the data cable and sealing air hose first run inside the workspace. An optional protective hose can enclose them up to the wall duct.

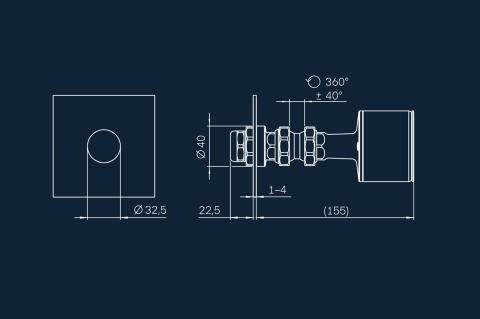

Magnetic Mounting

The magnetic mount is ideal for temporary installation or for finding the perfect camera head position inside the machine. The camera head is simply attached to the sheet metal wall at any desired point using a strong magnet.