Innovation & Best Practices Rotoclear Insights

New research project on AI-powered chip detection

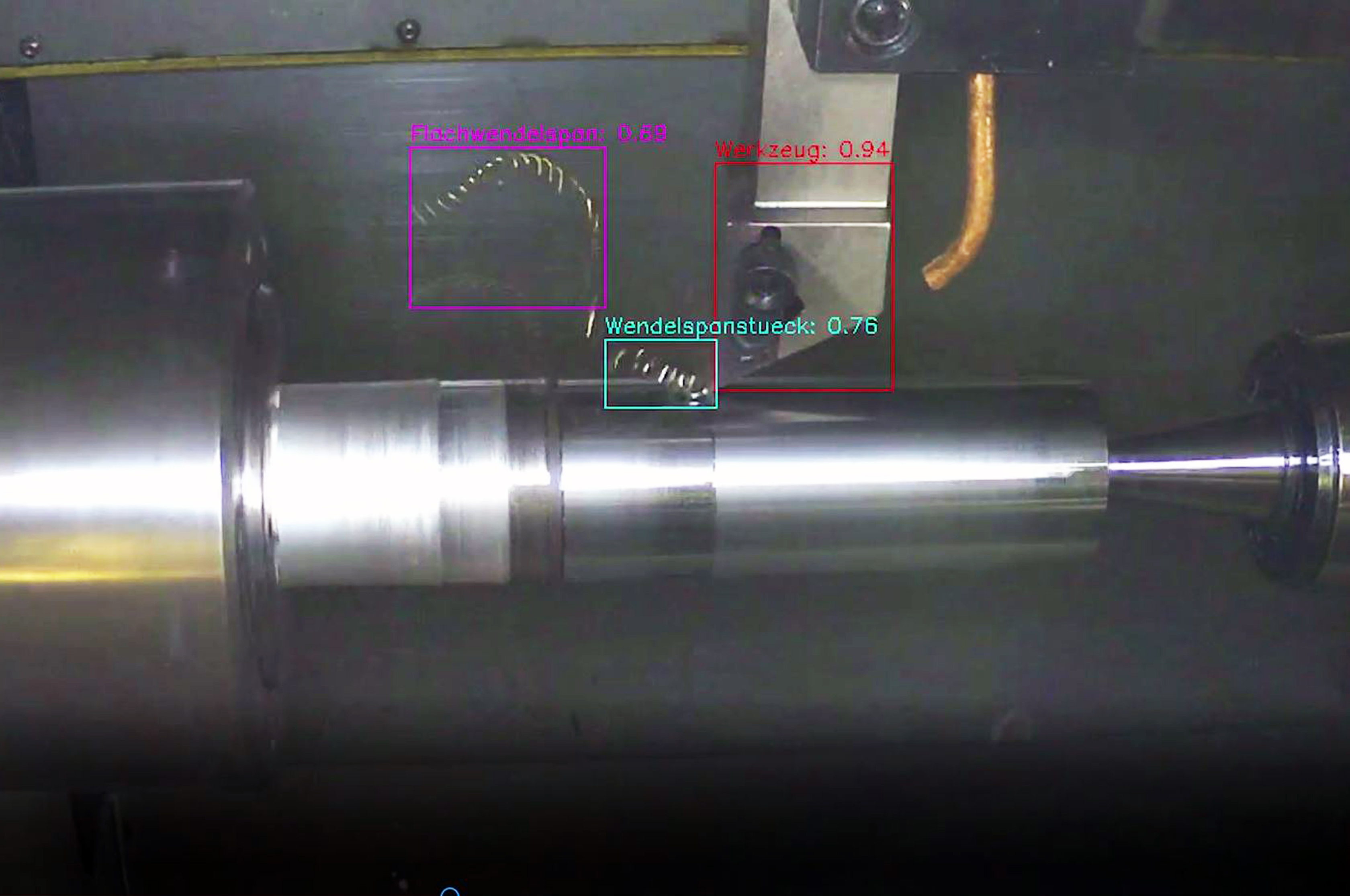

Chips are always produced during machining. That's already in the name. However, if the chips are particularly long or unfavorably shaped, they remain in contact with the workpiece, do not fall off and wrap around the tool or the workpiece once they reach a certain length. They can then damage one of the two and impair the surface and even the dimensional accuracy of the workpiece.

Automatic chip detection as the basis for real-time analysis

In order to eliminate such risks as far as possible in the future, the IFW (Institute of Production Engineering and Machine Tools) at Leibniz Universität Hannover is currently working with Rotoclear to develop a fully automated, AI-supported chip detection system - based on the hardware of the Rotoclear C2: The system detects the size of the chips produced in parallel with the process and can enable real-time monitoring and analysis on this basis in the future by integrating advanced image processing and machine learning.

The potential is enormous

"Critical chips can be identified immediately and intervention can be made in the production process to prevent damage to machines, tools or workpieces," explains IFW employee Lee Hartung.

"The potential of this technology in combination with our camera systems is enormous: if we bring the development to market maturity, it will prevent tens of thousands of crashes a year," adds Florian Friedrich, Managing Director of Rotoclear.

First insights into a technology of the future

You can see a demonstration of the first version of the chip detector here:

Exciting? If you would like to know more about the potential of advanced image processing and machine learning or have ideas for further applications, we are always happy to hear from you.