Expand your perspectives.

The Rotoclear C2:

The leading camera system for machine interiors.

Whether you’re looking for a clear view from the perspective of the tool or an overview of the machine interior, the self-cleaning Rotoclear C2 cameras create 4K views from revolutionary perspectives – even under the harshest conditions.

The intelligent control unit enables not only intuitive control with zoom feature, but also evaluation of saved videos and photos.

What the Rotoclear C2 offers you

The leading camera system for machine interiors will provide you with new information for optimising your machining processes. Of course, you can also easily share this valuable image information with others.

The Rotoclear C2 also forms the essential basis for automated image analysis – and thus for further automation of production.

The software behind it all

The clever software behind the Rotoclear C2 not only forms the basis for exact adjustment and intuitive camera control, but also offers all the interfaces necessary to stream, save and share image data with ease, including all conventional connection types (HDMI, USB, Ethernet) and protocols (e.g. TCP/IP, RTSP).

The features

Always a clear view

The high-speed spinning window in front of the camera lens always ensures a clear view of all machining processes, even in the presence of coolant and flying swarf and shavings.

High-resolution images

The camera head provides a livestream resolution of up to 4K with 60 frames per second (recording in HD and FullHD). But the images can also be scaled down to lower resolutions and refresh rates such as HD and FullHD. In both cases, you still have crystal-clear images, even in zoom mode.

Swipe zoom

Want to enlarge an image section? It’s easy: just swipe directly on the screen. Users can thus intuitively and quickly observe and analyse machining details.

Tool, top or side view

The Rotoclear C2 cameras can be mounted at the top (top view), on the side (side view) of the workspace or directly on the motor spindle (tool view). For clear views from revolutionary perspectives.

Double the perspective

Would you like to observe the process from two different perspectives at the same time? Not a problem. If you connect two camera heads to the control unit, you can observe machining, for example, from above and from the perspective of the tool at the same time.

Streaming and recording

The digital image data can be streamed live via HDMI, TCP/IP or RTSP and can also be recorded in HD and FullHD at any time, making them ideal for process optimisation as well as for sales and marketing purposes.

Perfect illumination

Exceptional images require perfect lighting, which is exactly why we’ve installed specifically developed premium Waldmann light sources in our camera heads.

Selection of connection options

Whether HDMI, USB or Ethernet cable, our control unit offer all the conventional connection options for fast and reliable transmission of image data – and integration of the system into the in-house network.

Flexible installation options

Wherever you would like to position your cameras, we offer all the options available for optimised, tailored camera setup, with numerous choices for fast and easy mounting in or on the wall (or at the top).

Extended range for large-capacity machines

With our signal amplifier C-Extender, the range of the Rotoclear C2 in large-capacity machines can be extended from 20 m to 40 m without any problems. If you combine two C-Extenders with each other, even a distance of 60 m is possible!

Foundation for analysis functions

The benefit of digital image data? They form the basis for automated analysis of machining processes. For example, processes could be automatically optimised, and tool and workpiece collisions avoided entirely in the future.

Remote Insights

Wherever you are in the world, whatever client you are using: The simple transmission allows you to view your image data remotely and flexibly at any time. The Rotoclear C2 not only enables remote analysis - it also makes process control more flexible.

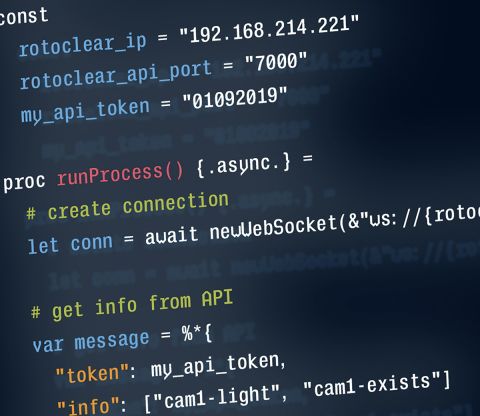

API

Do you want to implement new camera functions tailored specifically to your machine? No problem. Our API provides all the options you need to do this. For example, you can control the camera directly from your software application or automatically integrate image information into your program workflows.

Product development insights,

future prospects?

The product developer behind the Rotoclear C2, Manuel Linnenschmidt, talks about the considerations during development and the future potential of the camera system.

Dieser Inhalt eines Drittanbieters wird aufgrund Ihrer fehlenden Zustimmung zu Drittanbieter-Inhalten nicht angezeigt.

All the benefits

at a glance

The Rotoclear C2 grants insight into areas that are otherwise hidden by, for instance, cooling liquids or other elements in closed systems that block the view. The system reveals processes that are usually concealed to improve transparency, control and safety in production. Moreover, it allows you to share hidden processes with other departments, such as marketing or sales, or to use the data for training purposes.

Applications

- Monitoring of machining processes developed in-house (prototyping)

- Training

- Demonstrations by processing experts

- Trade fairs / showrooms

The Rotoclear C2 lets you view processes from the ideal perspective – from above (Top view), from the side (Side view) or even from the viewpoint of the tool itself (Tool view). This opens up completely new insights into your machining processes that you can learn exciting information from!

Applications

- Observation of machining processes in deep cavities

- Viewing of processes in large machines up close

Continuous visual information in real time is essential for optimum process monitoring. Only when you can view the entire process in real time can you also identify where something is going wrong or could be optimised.

Workpiece clamping is the perfect example of this principle: As soon as you discover a clamping error, you can stop the process immediately, vastly reducing scrap costs.

Applications

- Workpiece clamping check in series production

- Detection of undesirable chip clusters

Occasionally, we come across a process that regularly experiences errors, but the cause of these errors remains a mystery.

Continuous visual monitoring and process recording help you to find, understand and subsequently eliminate the causes of these errors.

Applications

- Determination of the causes of defective workpieces

- Discovery of the causes of crashes

- Identification of causes for handling errors when using automation components

Production processes need to be monitored constantly. Thanks to the remote feature of the Rotoclear C2, process monitoring can be carried out from wherever you are anywhere in the world.

And that’s not all: the camera system also lets you operate multiple machines at the same time. For example, you can simultaneously view several machines and monitor the corresponding processes on different screens using a production control station.

Applications

- Multi-machine operation (including for older machines)

- Avoidance of elaborate inspection rounds

- Improved flexibility for simplified shift planning

Whether you want to monitor tool breakage or detect chip clusters, the requirements for (automated) process monitoring are as diverse as the manufacturing processes themselves. For this reason, we have integrated an open API into our camera system for you.

This enables you to develop your own custom monitoring functions at any time to take the reliability, efficiency and precision of your machining processes to the next level.

Applications

- Tool inspection

- Workpiece position check

- Monitoring of environmental conditions

- Integration into monitoring systems

- Automated evaluation of images from the manufacturing process

What sort of equipment

do you need?

The Rotoclear C2 is available in multiple equipment variants for a variety of applications. These variants differ in terms of the number of cameras used, the selection of focus, the length of the data cable and the form of camera attachment inside the machine tool.

- Number of camera heads

- Focus

- Data cable

- Mount type

Number of camera heads

How many perspectives do you need? That’s the central question when it comes to the decision about the number of camera heads to install in your C2 system.

We offer kits with one or two camera heads. The dual kit allows you to observe your machining process from two different perspectives at the same time (e.g. top and tool view).

Focus

We have encapsulated the camera head to provide the best-possible protection from the harsh conditions inside the machine. This requires a preset focus.

You can choose between camera heads with different focus ranges for a variety of applications:

- F1: Focus in close range (tool-view)

- F2: Focus in far range (top/side view)

- F1+F2: Two lenses for close and far range

Selection of data cable

Our data cables ensure both fast and reliable data transmission. They’re suitable for use with drag chains and specially developed for harsh conditions inside the machine tool.

For your kit, you can choose between a 10 m (standard) and 20 m data cable.

Our C-Extender signal amplifier easily extends the range of the Rotoclear C2 from 20 m to 40 m for use in large-capacity machines. The range can even be extended to 60 m by combining two C-Extenders.

Selection of mount type

Regardless of what your machine looks like and where you would like to mount the cameras, Rotoclear offers you a whole host of mounting options.

Our flex arm mount is available for installation in sheet metal as well as for mounting on the wall or with magnetic attachment.

The ball mount surrounds the camera and can be installed directly in the machine wall. The benefit: interference contours are minimised, preventing to a large degree the accumulation of swarf.

Rotoclear C Basic, C2 and C Pro in comparison

In addition to the classic Rotoclear C2, we also offer the cost-effective Rotoclear C Basic and the Rotoclear C Pro to get you started in the world of camera systems for CNC machines. How do these camera systems differ in terms of functionality? Discover all the differences between the three systems.

Configure your optimal

C2 solution now.

Regardless of what your machine looks like and which requirements you have of your camera system, we can provide the perfect C2 kit for any application.

How to use:

Our downloads

Are you looking for detailed information or tips about optimal operation and maximum service life?

Our product brochure and our operating manual offer valuable answers to questions about the Rotoclear C2. Our latest Rotoclear C2 software brings you up to date.

But if you should have any other questions, you can, of course, contact us directly at any time.

Rotoclear C2 Operating Manual

(PDF, max. 7 MB)

German | English

Rotoclear C2 Security Analysis

(PDF, max. 200 KB)

German | English

Rotoclear C2 Software

(.fw-file, approx. 40 MB)

Latest version | Changelog