Why Blaser Swisslube trusts in Rotoclear.

Why does one of the most well-known manufacturers of cooling lubricants rely on camera systems and rotating windows from Rotoclear? Because it's the best way for Blaser Swisslube to make the strengths of its own products tangible. How exactly? We asked the customer themselves.

The Customer

The Swiss company Blaser Swisslube stands for lubricant solutions with measurable added value that are also gentle on people and the environment.

Through the combination of high-quality products, expert knowledge, and customized services, Blaser Swisslube helps manufacturing companies to fully exploit the potential of their machines and tools – and thus turn cooling lubricant into a key success factor.

The Challenge

How do you show the potential of your own products for process optimization when those same products make it difficult to observe the processes?

Making the potential of coolant lubricant solutions visible

This was the dilemma Blaser Swisslube faced: While the cooling lubricant experts' products can demonstrably optimize machining processes, in many cases they also make it difficult to showcase these improved processes due to the splashing cooling lubricants.

Making the potential of coolant lubricant solutions visible (Kopie)

This is exactly the challenge faced by Benjamin Roth, Process Engineering Manager, and his colleague Benjamin Sägesser, CNC Content-Creator: At Blaser Swisslube, they are responsible for making the machining processes, optimized with cooling lubricant solutions, tangible in videos.

Professionally filming CNC processes

But how do you optimally film the processes inside machine tools? "Some who produce CNC content deliberately run the machines without cooling lubricants for the recordings. For us at Blaser Swisslube, that's of course not an alternative," explains Benjamin Sägesser with a wink.

The Solution

So they began to search for a solution that would allow them to clearly capture and share the machining processes even when using cooling lubricant.

"We looked at a few systems back then, but the vast majority couldn't completely convince us," recalls Benjamin Roth. "It was different with Rotoclear: In terms of workmanship, robustness, reliability, and ease of use, the rotating windows and camera systems impressed us in every respect. And thanks to the spinning windows, you have a clear view of the processes in the machine despite the use of cooling lubricants."

Because it works reliably: How Rotoclear convinces in practice.

"When we record CNC processes, in most cases we only have one attempt. Everything has to be perfect," adds Benjamin Sägesser. "With the Rotoclear C Pro, the cameras always run flawlessly – and always provide us with clear images of the processes."

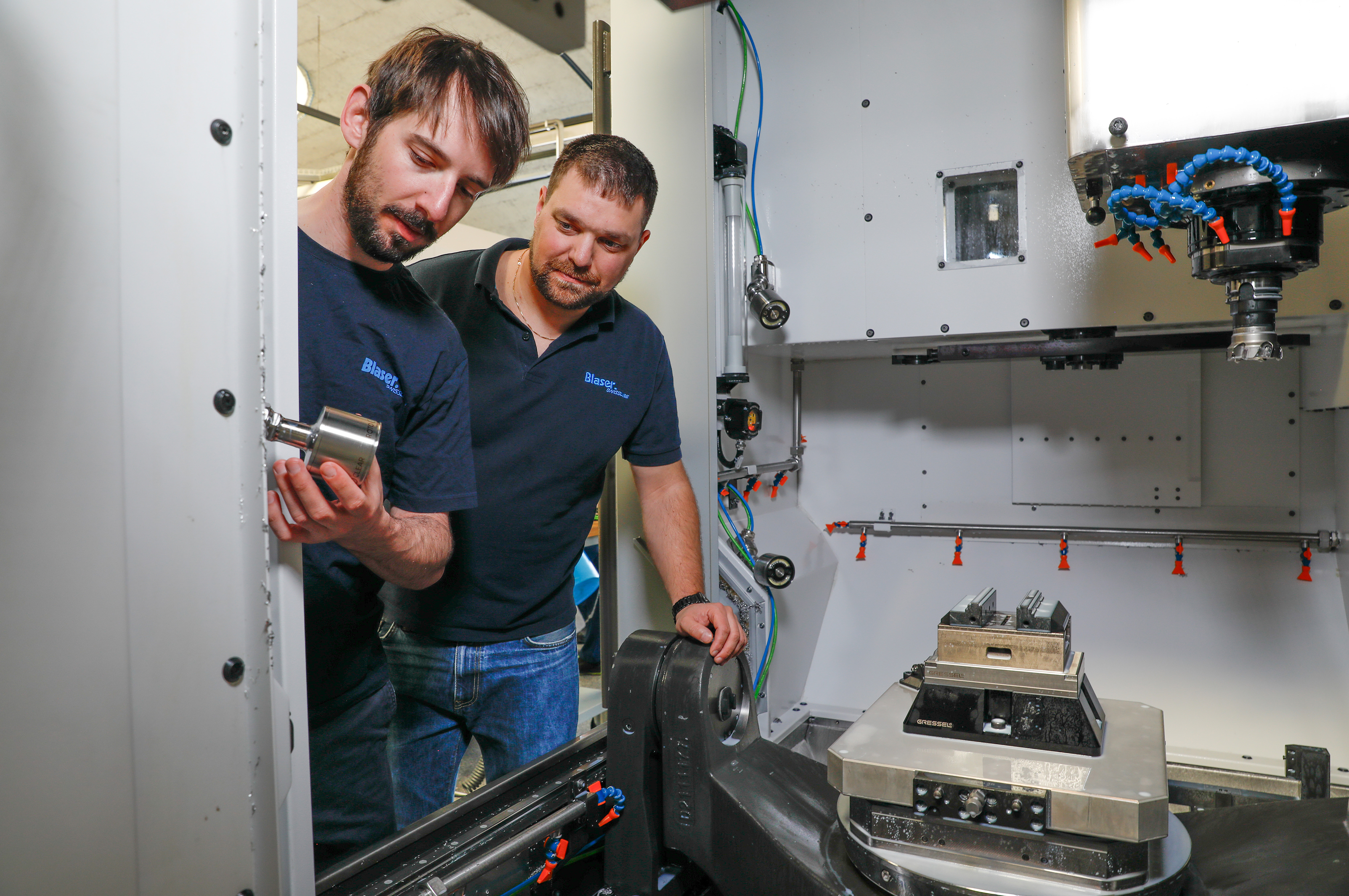

In addition to the Rotoclear S3 rotating window, Blaser Swisslube even uses three camera heads simultaneously in the machine for its CNC content to be able to show the processes from as many different perspectives as possible.

Four perspectives for exciting content

"To be able to cut optimally between different perspectives, we work with a total of three camera heads positioned at different locations inside the machine – and additionally with another handheld camera with which we film from the outside through the rotating window. This gives us an optimal selection of perspectives to play with," explains Benjamin Sägesser, describing the setup on the machine that Blaser Swisslube uses for CNC content production.

Slow motion, time-lapse, and optical zoom inspire

As Blaser Swisslube is always interested in the latest innovations from Rotoclear, the company now uses the newest product in the C-Line, the Rotoclear C Pro.

"The ability to record in slow motion or time-lapse is of course exciting for us," says Benjamin Roth. And Benjamin Sägesser adds: "The telephoto lens is also very cool. With it, we can now zoom without data loss – and thus have completely new possibilities to show details and set accents in our recordings."

The Results

With the Rotoclear S3 spinning window and the Rotoclear C Pro camera monitoring system, the CNC content team at Blaser Swisslube now has the optimal tools to produce high-quality videos of the machining processes using the best possible cooling lubricants.

See the results for yourself now – experience Rotoclear in action

How well does it work? On the Blaser Swisslube LinkedIn page or the company's YouTube channel you can see the results for yourself – and experience exciting content about the potential of cooling lubricants for optimizing manufacturing processes.

The Team Behind the Solutions

In addition to the easy-to-use, reliable, and inspiring products from Rotoclear, Benjamin Roth and Benjamin Sägesser were also impressed from the very beginning by the people behind the Rotoclear brand:

"The team at Rotoclear is really something special. We are in continuous contact and particularly appreciate that all our contacts always have a good basic understanding of the overall situation. Perhaps this is also due to the flat hierarchies, which enable faster communication and decision-making," says Benjamin Roth, summarizing his experience of the collaboration with the Rotoclear team.

"When we record CNC processes, in most cases we only have one attempt. Everything has to be perfect. With the Rotoclear C Pro, the cameras always run flawlessly – and always provide us with clear images of the processes."