Never miss a critical moment again: The Rotoclear C Pro continuously records your machining processes — even from multiple perspectives at once! Now you can monitor all processes inside your machine without any interruptions.

Detect the undetected:

With the Visual Backup of the Rotoclear C Pro

The Rotoclear C Pro automatically creates continuous ring-buffer recordings of your processes — called Visual Backups. Using the intuitive interface — Timeline — you can view and analyze them in real-time or at any time later.

Never miss a crucial moment again!

The Timeline makes it easier than ever to identify the root causes of errors in your machining processes — and it helps you in defining preventive solutions for the future.

The 11 benefits of the

Rotoclear C Pro

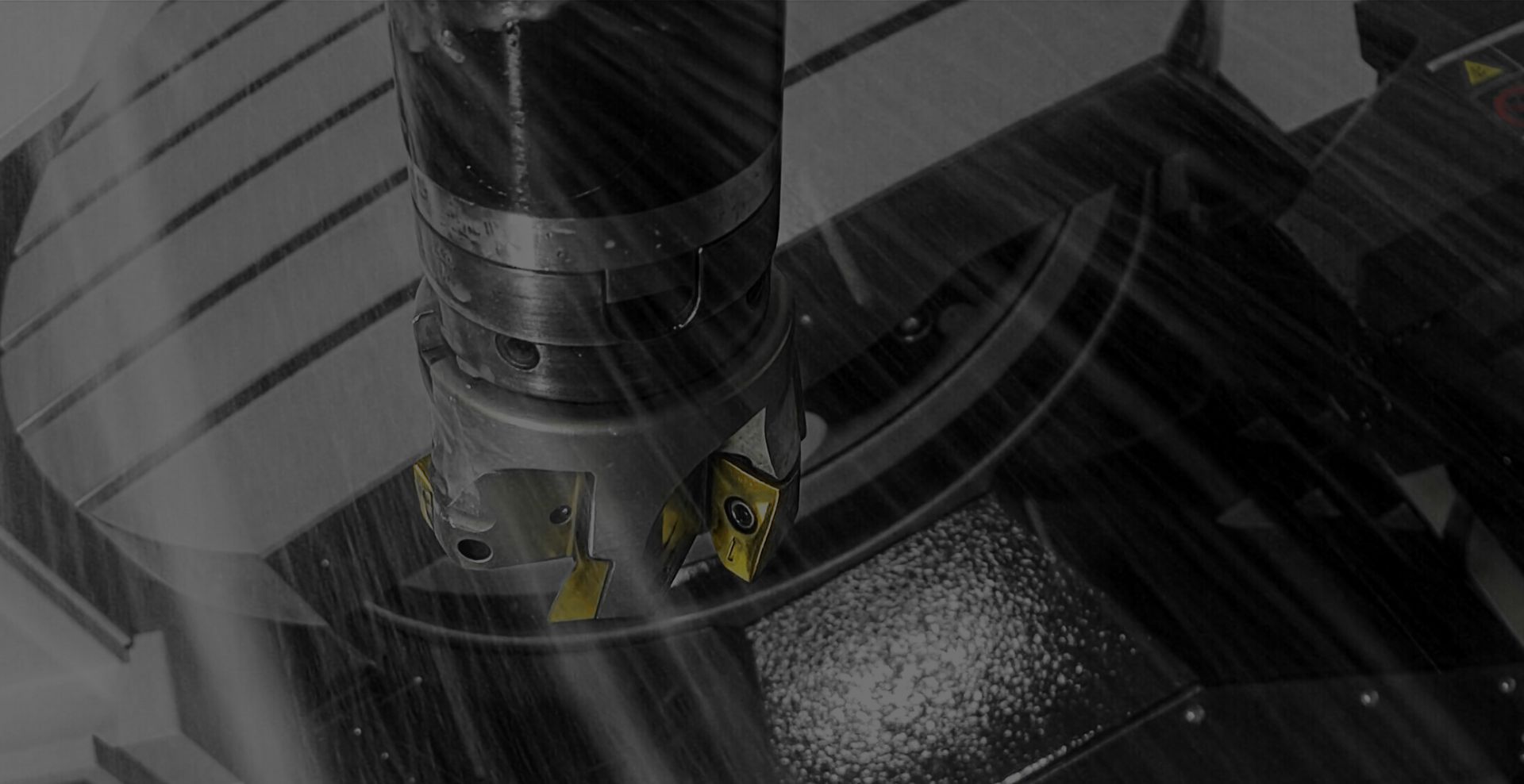

Continuously monitor machining processes visually

With the Rotoclear C Pro, you can continuously monitor machining operations and review them afterwards thus enabling such production benefits as more transparency, control, and safety.

Specific use cases:

- Controlling workpiece clamping in series production

- Detecting unwanted chip nests

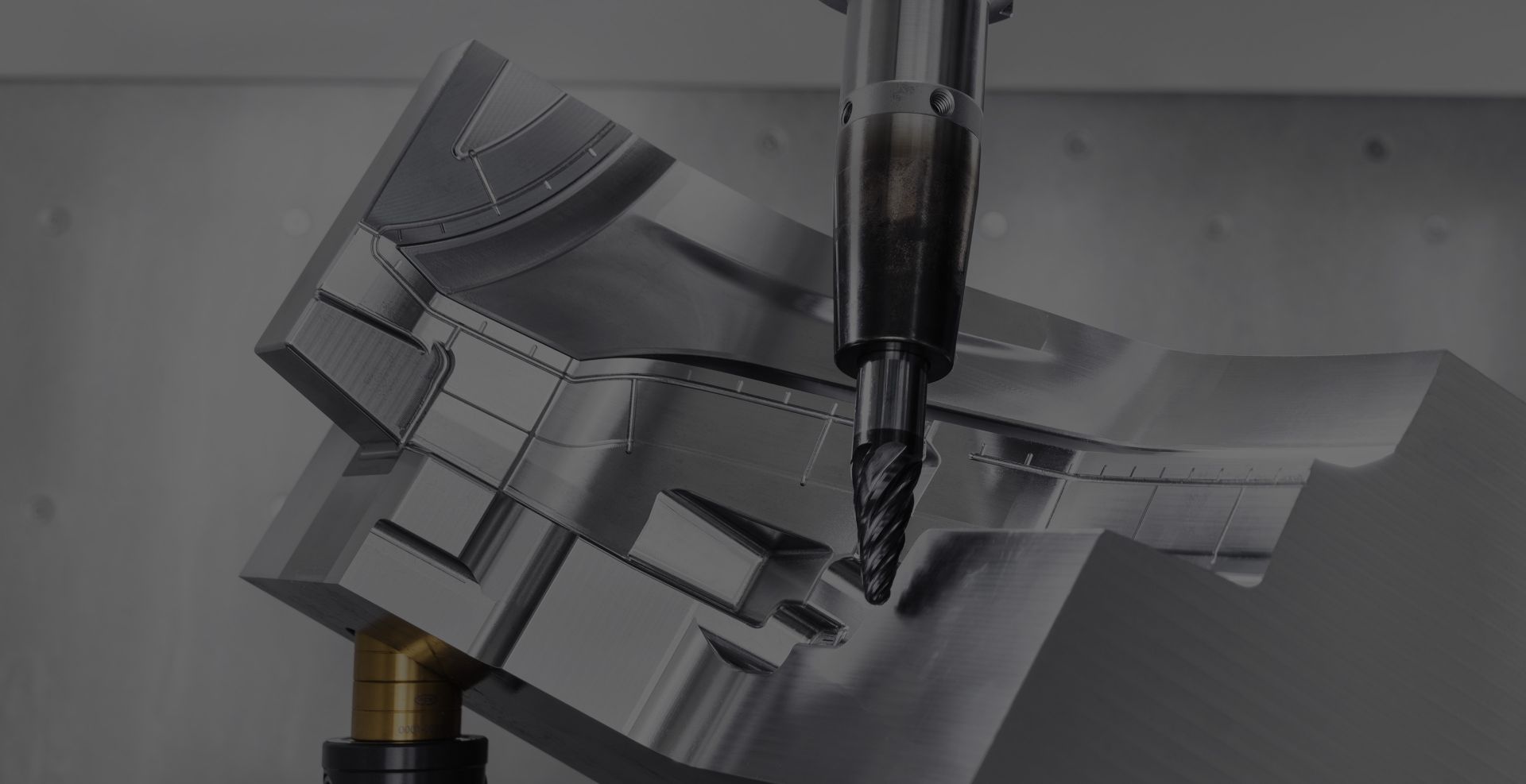

Observe machining from new perspectives

With a system featuring two camera heads, you can monitor your processes from two perspectives at once, gaining new insights and identifying opportunities for improvement.

Specific use cases:

- Inspecting tiny geometries in detail

- Observing processes in deep cavities

- Getting close-up views in large machines

Inspect workpiece or tool details precisely

With up to 4K resolution and intuitive zoom, the Rotoclear C Pro telemetric lens allows you to examine critical areas closely and inspect even the smallest details visually.

Specific use cases:

- Check tool wear

- Quality management of workpieces

- Verify clamping (even on tiny components)

Identify and understand error causes

With the Rotoclear C Pro, you can tag special events in the video file and analyze them later at your convenience.

This allows you to identify, understand, and eliminate error sources.

Specific use cases:

- Tag and analyze tool breakage

- Tag crashes and determine causes

- Identify sources of defective workpieces

- Detect handling errors when using automation components

Enhance employee safety

The Rotoclear C Pro provides detailed, continuous insights into the machine interior without exposing personnel to unnecessary hazards.

Specific use cases:

- Safely check tool condition from outside

- Verify clamping from outside

- Safely monitor the formation of chip nests from outside

Streamline process monitoring

The system also supports multi-machine operation — for example, via a production control station where you can view several machines at once and monitor processes on one or multiple screens via the ONVIF interface.

Specific Use Cases:

- Multi-machine operation (also for older machines)

- Avoiding time-consuming inspection rounds

- Remote monitoring from home office

- Increased flexibility for easier shift planning

Continuously improve manufacturing processes

The Visual Backup turns the camera into a video surveillance system for your CNC machine. This allows you to review processes in detail afterwards and uncover opportunities for optimization.

Specific Use Cases:

- Minimize scrap costs

- Reduce tool costs

- Prevent crashes

- Optimize machine utilization

Seamless process documentation for enhanced security

Concrete video documentation that gives you real peace of mind.

Specific Use Cases:

- Documentation as a basis for post-calculation

- Video proof of correct processes in case of discrepancy

Record and share processes in slow motion or time-lapse

This not only enables more detailed analysis of specific operations but also makes it easy to share visually impressive recordings with others.

Specific Use Cases:

- Marketing videos

- Support for sales processes

- Machine operator training, etc.

Develop custom monitoring solutions via API

That’s why we’ve integrated an open API into our camera system, giving you the ability to develop your own monitoring functions and take the reliability, efficiency, and precision of your machining processes to the next level.

Specific Use Cases:

- Tool checks during tool changes

- Workpiece position verification

- Monitoring the environmental conditions inside your machines

Leverage automation potential

Once linked, the system can automatically tag and label selected process states or alerts in real time — fully automated, without any manual intervention.

Specific Use Cases:

- Integration into other monitoring systems

- Automated evaluation of production process images

- Automatically tag events in recordings when machine errors occur

Rotoclear C Pro key applications

Monitoring large production batches

Observing machining of complex components

Targeted, long-term process optimization (CIP)

Process documentation (e.g., as a basis for post-calculations)

Tag & Spot: Mark and analyze process deviations in video.

In the Timeline of the Rotoclear C Pro, you can easily tag specific events (e.g., process deviations) for quick retrieval and targeted analysis later.

If you connect the system directly to your machine control system via the API, the Rotoclear C Pro can even automatically mark certain events (e.g., tool changes, etc.) on the timeline for you.

Additional Features of the Rotoclear C Pro

Always a clear view thanks to spinning windows

Our camera heads are specially designed for CNC machines: the fast-spinning window in front of the lens ensures a clear view of all machining processes, even when using coolant or dealing with flying chips.

High resolution for sharp images

Our camera heads deliver up to 4K resolution at 60 frames per second in live streaming (manual recordings in HD or FullHD). Images can also be transmitted at lower resolutions or frame rates, such as FullHD — still producing sharp images even when zoomed.

Up to two perspectives at once

Want to observe your manufacturing process from two perspectives simultaneously? No problem. By connecting two camera heads to the control unit, you can, for example, monitor machining both from above and from the tool’s perspective at the same time.

Free choice of perspective(s)

The Rotoclear C2 cameras can be mounted on the ceiling (Top View), on the side (Side View) of the workspace, or directly on the spindle (Tool View) — giving you clear insights from revolutionary perspectives.

Seamless video monitoring (Visual Backup)

The Rotoclear C Pro automatically records your production processes continuously and stores the video data in intelligent cycles over a set period. Using the intuitive timeline, you can seamlessly review and analyze past moments of the production process at any time.

Intuitive Timeline UI

Seamlessly switch between past footage and real-time views: the Rotoclear C Pro’s user interface has been completely redesigned. The timeline lets you intuitively toggle between previously recorded video and live views of your machine.

Large internal storage

To get started right away with your Visual Backups, the Rotoclear C Pro comes with up to 4 terabytes of storage. This allows you to store roughly up to 30 days of video footage and review it anytime for detailed analysis.

Slow-motion and time-lapse recording

Capture high-speed processes in slow motion for detailed analysis. For practical summaries of long machining operations, time-lapse recording is also available.

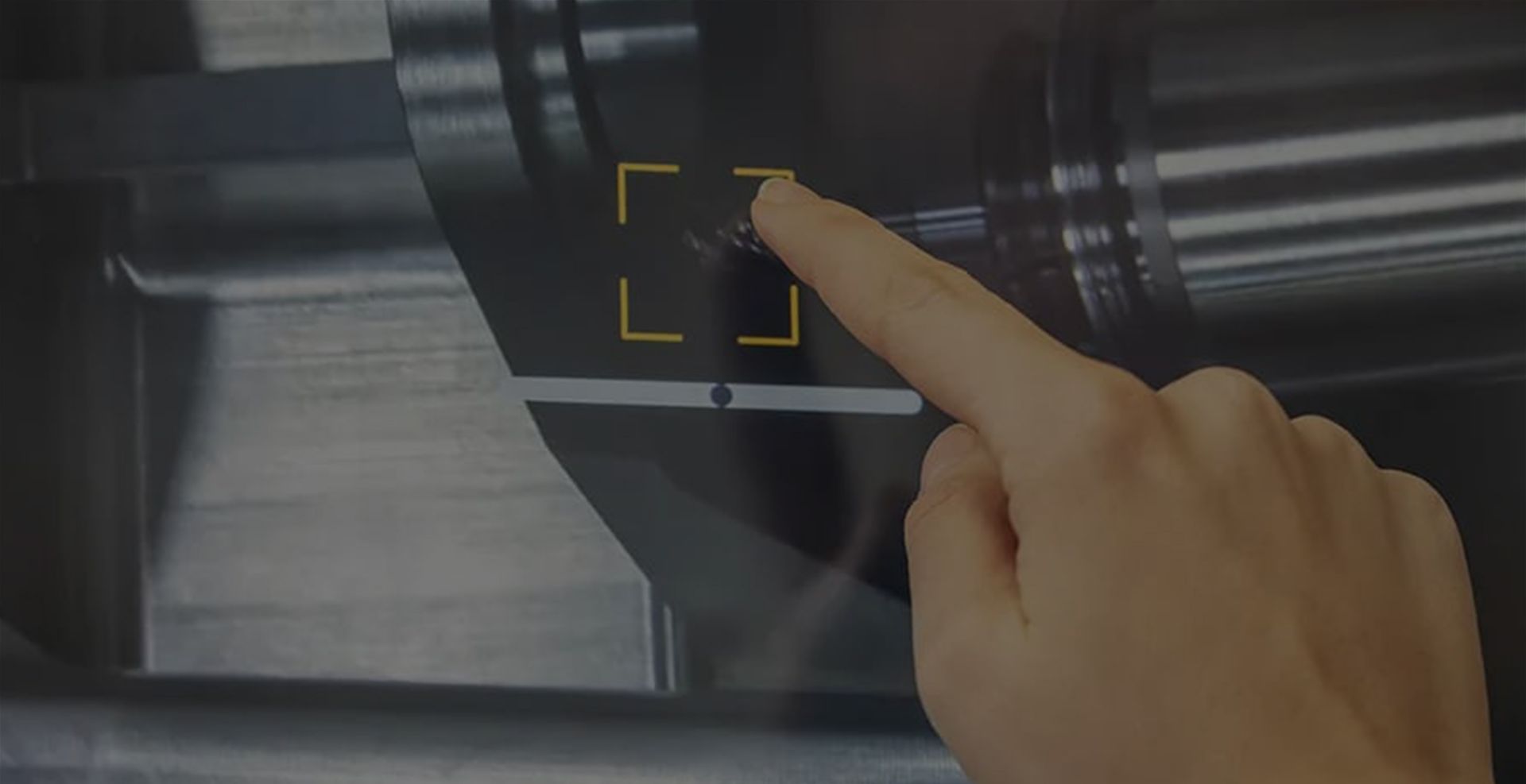

Tap focus for flexible focus adjustment

Optional camera heads with focusable lenses (wide-angle and telemetric) allow you to focus on a specific area with just a tap on the screen — ideal for monitoring a critical spot that isn’t in the default focus.

Swipe-Zoom

Want to zoom in on a section of the image? Simply swipe directly on the screen. Users can intuitively and quickly examine and analyze details of the machining process.

Network streaming

With network streaming, you can access your image data remotely at any time. The Rotoclear C Pro not only enables remote analysis, but also makes process monitoring more flexible.

Streaming & recording simultaneously

Video data can be recorded manually or continuously by the system (e.g., as MP4) and analyzed later via the web interface. The system supports simultaneous live streaming via DisplayPort, HDMI, Ethernet, ONVIF, or RTSP — giving you a direct real-time view of your machine.

Perfect illumination

Excellent images require perfect lighting conditions: that's why we have installed premium light sources from Waldmann in our camera heads, specially developed for this application.

Wide range of connectivity options

For real-time streaming, you have both DisplayPort and HDMI connections. Two 1-Gbit Ethernet ports allow video data to be transmitted to a local network or the web. In addition, the system includes four USB 3.0 ports for flexible integration.

Flexible mounting options

No matter where you want to place your camera(s): with numerous options for quick and easy mounting —whether through-wall, pre-wall, or on the ceiling—to create a customized and optimized camera setup. Using a magnetic mount, you can first find the perfect position for the camera head in the machine with complete flexibility.

Open API for custom automation

The open API lets you integrate all signals from your machine into the Rotoclear C Pro. This enables the system to automatically mark specific events (e.g., tool changes) or even detect certain conditions (e.g., chip accumulation) automatically. View Documentation

Outlook:

Image data for AI-Powered process monitoring

Whether it‘s about tool breakage detection, chip nest detection, or the automatic analysis of idle times: The possibilities for using AI for automated analysis of image data are endless.

Future solutions will include the ability to use the Rotoclear C Pro for your process monitoring with our AI-solutions on board.

Rotoclear C Basic, C2 and C Pro

side by side

Not in need of automatic recording of your processes? Or maybe you only want real-time insights from a single perspective?

If so, the Rotoclear C2 or C Basic might be the right solution for you. Check out the differences and find your solution!

All-in-one system for easy setup

The Rotoclear C Pro comes with everything you need to get your camera monitoring system up and running in no time: along with the camera head and control unit, all necessary cables, connectors, and mounts are included. You define the exact configuration yourself.

Find your perfect perspective!

With our camera systems, you can observe machining details up close — or monitor the entire machine interior. If desired, you can watch processes from two perspectives simultaneously.

From the tool's perspective: : Tool View

Want to observe the machining process up close? Rotoclear camera systems are designed so that a camera head can be mounted directly on the spindle housing, right by the tool holder. In most cases, however, this should be taken into account already during the machine’s configuration.

- The benefits: This perspective allows users to always keep a close eye on the tool, giving them uniquely detailed insights into the machining process.

- Our tip: The integration of this camera perspective should be taken into account when configuring the machine. If you are interested, ask your machine manufacturer about the “Tool View” option.

View from above: Top View

The perspective from the machine ceiling looking down, with the entire machine room in view, is the perfect complement to the tool view perspective.

- The benefits: Top View enables users to maintain their orientation, as reference points and automation components remain in view alongside the overall situation.

- Our tip: If you consistently align the camera along an X, Y, or Z axis, orientation will be even easier for users.

View from the side: Side View

Viewing the machining processes from the side can be useful in various situations: On the one hand, users can keep an eye on tool changes at all times. On the other hand, the side view is also a good alternative when it is not possible to install a tool view.

- The benefits: The side view allows for detailed shots without losing sight of the immediate surroundings (such as the tool changer).

- Our tip: If you retrofit a Rotoclear camera system in your machine, the side-view perspective is the perfect alternative for getting as close as possible to the machining process from the outside.

How to configure your Rotoclear C Pro

The Rotoclear C Pro is suitable for a wide variety of machine types and applications. Depending on the size of your machine and the desired camera position, we offer system setups with different configuration options.

Use the online configurator to easily put together your individual system. You’ll then receive a tailored quote for your setup instantly.

Was können Sie konfigurieren?

For different applications, you can choose between camera heads with varying depth-of-field ranges:

- F1: Close-range focus (200–500 mm — camera positioned near the tool)

- F2: Long-range focus (500–6000 mm — camera mounted on ceiling or wall)

- F1 + F2: Camera head with a choice between F1 and F2

- TFT: Tap Focus telemetric lens (liquid lens)

- TFW: Tap Focus wide-angle lens (liquid lens)

Note: You can also combine the TFT lens in a camera head with either an F1 or an F2 lens.

Our data cables are available in two lengths. If needed, you can extend them up to 60 m using a signal amplifier (C-Extender).

- 10 m (standard)

- 20 m

- 40 m = 20 m + 20 m → C-Extender required

- 60 m = 3 x 20 m → 2 x C-Extender required

No matter the design of your machine or where you want to mount the cameras, we have the optimal solution for you:

- The ball mount houses the camera and can be installed directly on the machine wall. The advantage? Its minimized profile reduces the risk of chip accumulation.

Learn more about the ball mount - Our flex-arm mount offers maximum flexibility in angle and perspective. It is available for through-wall mounting, pre-wall mounting, or with a magnetic mount.

Learn more about the flex-arm mount

Installation Dimensions

- The Rotoclear C Pro camera head has a diameter of 70 mm and a length of 50 mm (without mount).

- The Control box measures 110.5 × 80 × 28 mm.

- Both components are compact and can be mounted flexibly.

All downloads for Rotoclear C Pro

Looking for detailed information, tips for optimal operation, or ways to maximize service life? Here you’ll find everything available for free download.

Rotoclear C Pro Operating Manual

(PDF, max. 8 MB)

Deutsch | Englisch

Rotoclear C Pro Software

(.raucb file, approx. 120 MB)

Current version | Changelog

Accessories or spare parts for the Rotoclear C Pro? Find and order now.

Need accessories or spare parts for the Rotoclear C Pro? Our configurator helps you quickly find exactly what you need — and order it directly. Everything will be delivered to you in no time!