Configuration & installation

Before installing our camera systems, you should carefully consider the choice of the optimal viewing perspective as well as the most suitable mounting option for the camera heads.

Here, we also provide valuable tips for mounting the camera heads and integrating the control unit.

Configuring the optimal perspective(s)

Whether from above (machine ceiling), from the side, or up close from the tool’s own point of view – our camera systems enable a wide range of revolutionary perspectives. Which one makes the most sense for your machine is up to you.

From the tool’s perspective: Tool View

Want to observe machining from close range? Rotoclear camera systems are designed so that a camera head can be mounted directly on the spindle head, close to the tool holder. In most cases, this should already be taken into account during machine configuration.

- Benefits: This perspective allows operators to keep the tool in full view at all times – and gain uniquely detailed insights into the machining process.

- Our tip: Integration of this camera perspective should ideally be considered during machine configuration. If interested, talk to your machine manufacturer about the “Tool View” option.

From Above: Top View

The perspective from the machine ceiling down into the entire working area is the perfect complement to the Tool View.

- Benefits: Top View helps operators stay oriented, since they can see the overall machining process as well as reference points and automation components.

- Our tip: Aligning the camera consistently with one of the X, Y or Z axes makes orientation even easier.

From the Side: Side View

Viewing the machining process from the side can be useful in various situations: operators can always monitor tool changes, and Side View is also a great alternative if Tool View installation is not possible.

- Benefits: Side View provides detailed process views without losing sight of the immediate surroundings (e.g. tool changer).

- Our tip: If you are retrofitting a Rotoclear camera system into your machine, Side View is the perfect alternative to stay close to the machining process from outside.

The optimal focus

To best protect the camera against the harsh conditions inside the machine, the camera head is encapsulated – normally requiring a pre-set focus. Depending on your application, you can select camera heads with different focus ranges during system configuration:

The F1 lens has a focus range of 200 to 500 mm, making it ideal for situations where the camera is positioned close to the action – for example, from the tool’s perspective (Tool View).

The F2 lens offers a focus range of 500 to 6000 mm. It is used when the camera needs to cover a larger area – for example, from the Top View perspective.

You can also equip your camera head with two different lenses (and thus two focus ranges). This gives you maximum flexibility when it comes to camera positioning and perspective.

For the Rotoclear C Pro, we also offer – in addition to the fixed-focus options above – a camera head equipped with a liquid lens (available as telephoto or wide-angle). This allows you to adjust the focus flexibly to different points in the workspace with just a tap.

The right data cable

Our data cables ensure fast and reliable data transmission. They are resistant to coolant and lubricants, drag-chain compatible, and specially designed for the tough conditions inside a machine tool.

The data cables are available in two lengths:

- 10 m (standard)

- 20 m

In large-scale or portal machines, a cable length of more than 20 m may be required. For these cases, we have developed our “Rotoclear C-Extender” (signal amplifier). Connected to the data cable, it can extend the range from 20 m up to a maximum of 60 m.

- 40 m = 20 m + 20 m → Rotoclear C-Extender required

- 60 m = 3 x 20 m → 2x Rotoclear C-Extender required

Mounting the camera heads

We don’t know exactly what your machine looks like or where inside the machine you want to position the camera heads. The requirements can vary greatly. That’s why Rotoclear offers you three different mounting options.

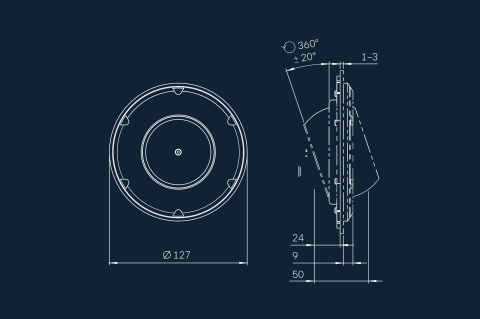

Advantages of the ball mount

The ball mount is the most elegant installation option for your camera heads: the camera is integrated directly into the sheet metal wall, making it a discreet part of the machine interior.

- Within the ball mount, the camera can be tilted by ±20° and rotated 360°.

- Because it protrudes only minimally into the workspace, chip nests hardly form in this area.

Installing the ball mount

The ball mount can be installed entirely from within the machine’s working area. There are two installation variants:

- Variant A: A mounting cut-out with a diameter of 115 mm is required. The housing of the ball mount can then be installed in the cut-out using the counterholder.

- Variant B: A mounting cut-out with a diameter of 98 mm including 6 × M5 threaded holes is required. The housing of the ball mount can then be screwed directly into the sheet metal wall without the counterholder.

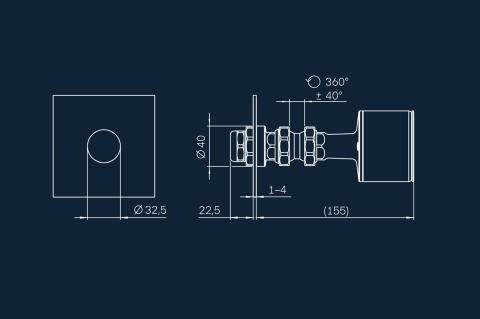

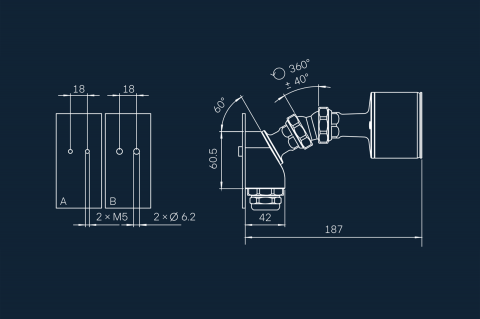

Advantages of the flex arm Mount

With the Flex Arm Mount, the camera is installed on a ball-joint arm at the front, allowing it to extend further into the workspace. The Flex Arm can be integrated into the sheet metal wall, mounted in front of the wall, or simply fixed in place with a magnet for maximum flexibility.

Because the Flex Arm can be tilted by ±20° and rotated 360° at each of its joints, it’s even easier to adjust the camera to the optimal perspective. The arm also helps reduce the distance to the observed process.

- Tip: With additional joints in the Flex Arm Mount, the camera can be positioned even more freely in the workspace and placed closer to the machining process. An optional protective hose ensures that all supply lines are optimally protected in the working area.

Through-wall mounting

For through-wall mounting, a hole is drilled in the sheet metal wall and the flex arm mount is screwed directly to it. This allows both the data cable and the sealing air hose to be routed outside the workspace.

Pre-Wall Mounting

In pre-wall mounting, the Flex Arm Mount is fixed on a base in front of the wall inside the machine. In this case, the data cable and sealing air hose first run inside the workspace. An optional protective hose can enclose them up to the wall duct.

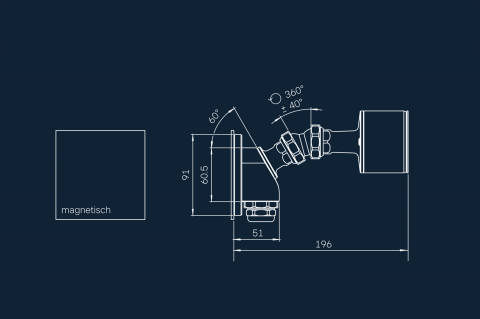

Magnetic Mounting

The magnetic mount is ideal for temporary installation or for finding the perfect camera head position inside the machine. The camera head is simply attached to the sheet metal wall at any desired point using a strong magnet.

Mounting on the spindle head

Mounting in direct proximity to the tool holder enables process observation from the tool’s own perspective (Tool View). This revolutionary viewpoint is available exclusively with the Rotoclear C2.

Benefits of spindle head mounting

Mounting on the spindle head allows you to observe machining processes from extremely close range: The tool always remains prominently in view, so even fine machining details can be seen clearly.

Installing on the spindle head

The compact and robust design of the camera head makes it possible to integrate it directly into the spindle head with many machine setups. Ideally, the machine manufacturer should consider this integration already at the design stage.

If you are interested, please contact your machine manufacturer directly. We will gladly support the integration process at any time.

Options for custom mounting

Of course, you can also attach the camera head using a custom-developed fixture beyond the options described above. Simply use the mounting holes on the back of the camera head. Questions? Feel free to contact us.

Installing on the spindle head

The compact and robust design of the camera head makes it possible to integrate it directly into the spindle head with many machine setups. Ideally, the machine manufacturer should consider this integration already at the design stage.

If you are interested, please contact your machine manufacturer directly. We will gladly support the integration process at any time.

Integration of the control unit

The control units of our three camera systems differ, among other things, in the range of connection options available:

| Rotoclear | C Basic | C2 | C Pro |

| HDMI | |||

| USB | (for updates) | 2.0 | 3.0 |

| Ethernet | 1 x 100 Mbit, 1x 1 Gbit | 2 x 1 Gbit | |

| RTSP protocols | |||

| DisplayPort | |||

| Internal hard drive |

The control unit is typically installed in a control cabinet. For DIN rail mounting, you can use the pre-assembled DIN rail clip.

For Rotoclear C2 and Rotoclear C Pro, the user interface can also be integrated directly into your machine control system – as is already the case with DMG MORI.

Thanks to the integrated API, both systems can also be connected to other systems or software applications.

With all three systems, a monitor or touch display can be connected directly to the control unit via HDMI.

The camera system can be connected to two separate networks or linked directly to a computer via Ethernet.

More details on installation and integration?

You’ll find comprehensive information on setup and configuration, along with many other valuable tips, in the operating manuals for our three camera systems.

Rotoclear C Basic Operating Manual

(PDF max. 8 MB)

German | English

Rotoclear C2 Operating Manual

(PDF max. 9,2 MB)

German | English

Rotoclear C Pro Operating Manual

(PDF max. 9,3 MB)

German | English

The right software for your control unit?

Looking for the latest software for your control unit? All downloads are available here.

Rotoclear C Basic Software

(.fw-Datei, approx. 50 MB)

Latest version

Rotoclear C2 Software

(.fw-Datei, approx. 50 MB)

Latest version

Rotoclear C Pro Software

(.raucb-Datei, approx. 150 MB)

Latest version

Accessories & spare parts for our camera systems

Do you need spare parts or accessories for the Rotoclear C Basic, Rotoclear C2, or Rotoclear C Pro? With our configurator, you’ll quickly find exactly what you need.

Your support contacts for our camera systems

Still have questions about installation, even after checking the configuration and installation guide? Then please don’t hesitate to contact our support team.

Need help with setup or installation?

Markus Reiss

Need help with the software for our camera systems?

David Jäckle

Need support with a repair or claim?