New perspectives on enhancing your machining

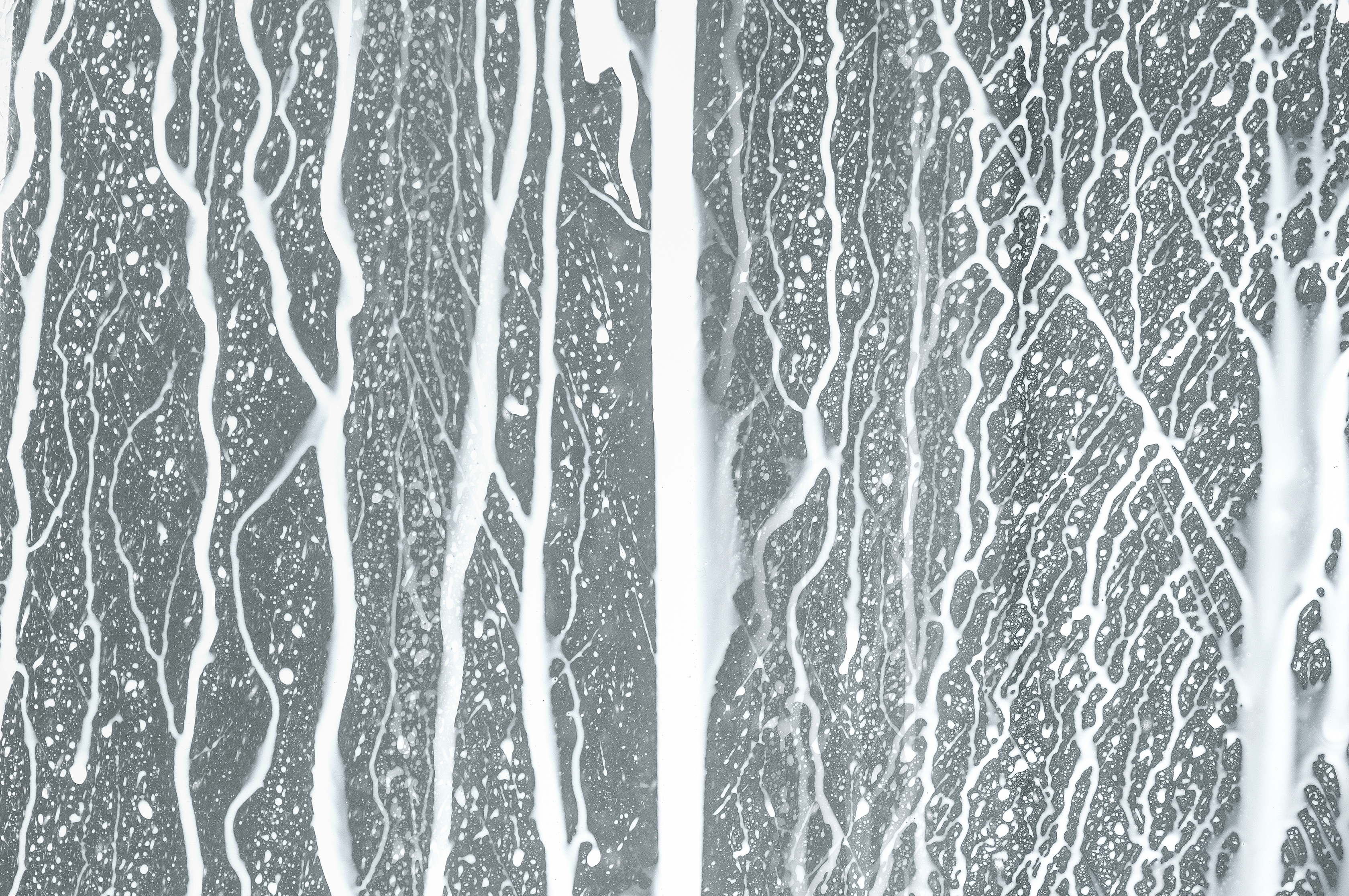

Making machining processes more efficient while improving process quality: When it comes to optimizing their manufacturing workflows, the machining industry has yet to tap into its full potential. One key challenge lies in the nature of the process itself: The use of cooling lubricants to preserve tools and the constant chip ejection have long turned machining into a kind of "black box", making detailed analysis extremely difficult.

Initially, spinning windows on the machine windows offered a solution. These allowed machine operators to constantly monitor the process from outside—and to use visual feedback for potential process improvements. These systems still hold value today. But some details remain hard to detect from the outside looking in.

Advantages of camera systems

What if high-resolution image data from inside the machine were available—from new perspectives that are normally beyond human vision? What if you could view the workpiece from above, or even observe the machining process in razor-sharp detail from the perspective of the tool itself?

The answer came in 2019 with the invention of a robust camera system specifically engineered for the extreme conditions inside a machine tool. The first Rotoclear Camera (short version: Rotoclear C) was born.

Revolutionary perspectives for new insights

This innovation opened up – quite literally – revolutionary perspectives. The image data obtained provides companies with the basis for entirely new insights: for example, the causes of crashes between tool and workpiece can be analyzed even more precisely – and crashes can be avoided in the future. This saves time and valuable resources. The visual analysis also allows for the optimization of machining processes – with corresponding improvements in quality and efficiency. Find out exactly how in the following article…

How the camera systems work

-

How do camera systems in machine tools work?

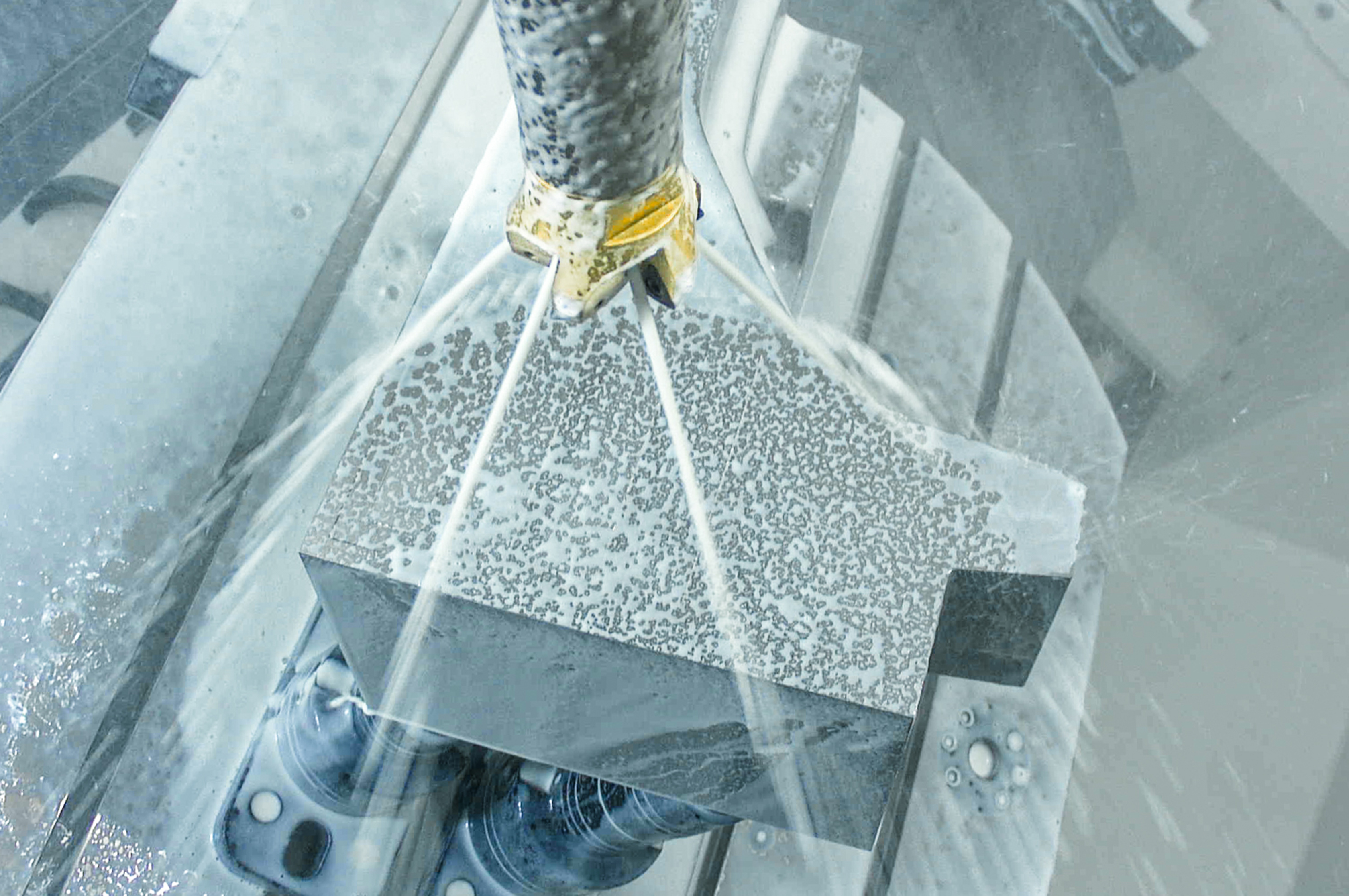

During the machining process within a machine tool, very harsh conditions prevail: constant flying chips and splashing cooling lubricant create an inaccessible environment where conventional camera systems cannot be used effectively. Firstly, the cooling lubricant quickly wets the lens of a conventional camera – increasingly impairing visibility. Secondly, "normal" cameras cannot withstand the constant flying chips – and are quickly destroyed by the mass of tiny projectiles.

A combination of rotation and robustness

With the invention of the first Rotoclear Camera, product developers solved both problems at once: firstly, with a particularly robust housing that permanently withstands the harsh conditions inside the machine tool. Secondly, with a rapidly spinning window in front of the lens, a principle familiar from spinning windows.

For convenient operation and integration into the machine control system or networks, advanced camera systems also feature their own control unit.

Optimize manufacturing processes

-

How camera systems can optimize manufacturing processes

Beyond the mere possibility of closely monitoring and controlling their own processes, camera systems offer manufacturing companies a whole range of benefits: they not only have the potential to sustainably increase the quality of processes and results but can also significantly contribute to increased productivity and enhance employee safety.

-

- Improving process quality

- Increasing productivity

- Improving safety

How camera systems contribute

to quality improvement

The new perspectives from cameras onto the tool and workpiece allow for their condition and position to be precisely checked before start-up. This enables companies to prevent potential errors in advance, detect possible tool wear early, and thus significantly increase their machining accuracy. The result? Less scrap and precisely manufactured components.

Goodbye Crashes! Visual monitoring with camera systems allows you to detect potential collisions in advance. For example, during setup, you can see when the tool and workpiece are getting too close – and stop the process before they collide. This not only saves you on scrap costs but also on the costs of machine downtime.

How camera systems

can increase productivity

Constant insight from the outside into the machine's interior leads to fewer production interruptions: for example, no one needs to open the machine door anymore to check the position of the tool and workpiece. This saves time every day, which adds up over longer periods and has a measurable impact on productivity.

Special events during the manufacturing process can also be specifically analyzed. The valuable visual information in the form of camera images allows machine operators to find the causes of errors – and to rectify them for the future. This sustainably increases process quality.

Could chip flow be optimized? Is the tool spindle taking unnecessary paths? Besides detecting errors, observation from multiple perspectives can, of course, also reveal new potential for further optimizing machining processes. With the new image data, companies can continuously improve their own manufacturing processes.

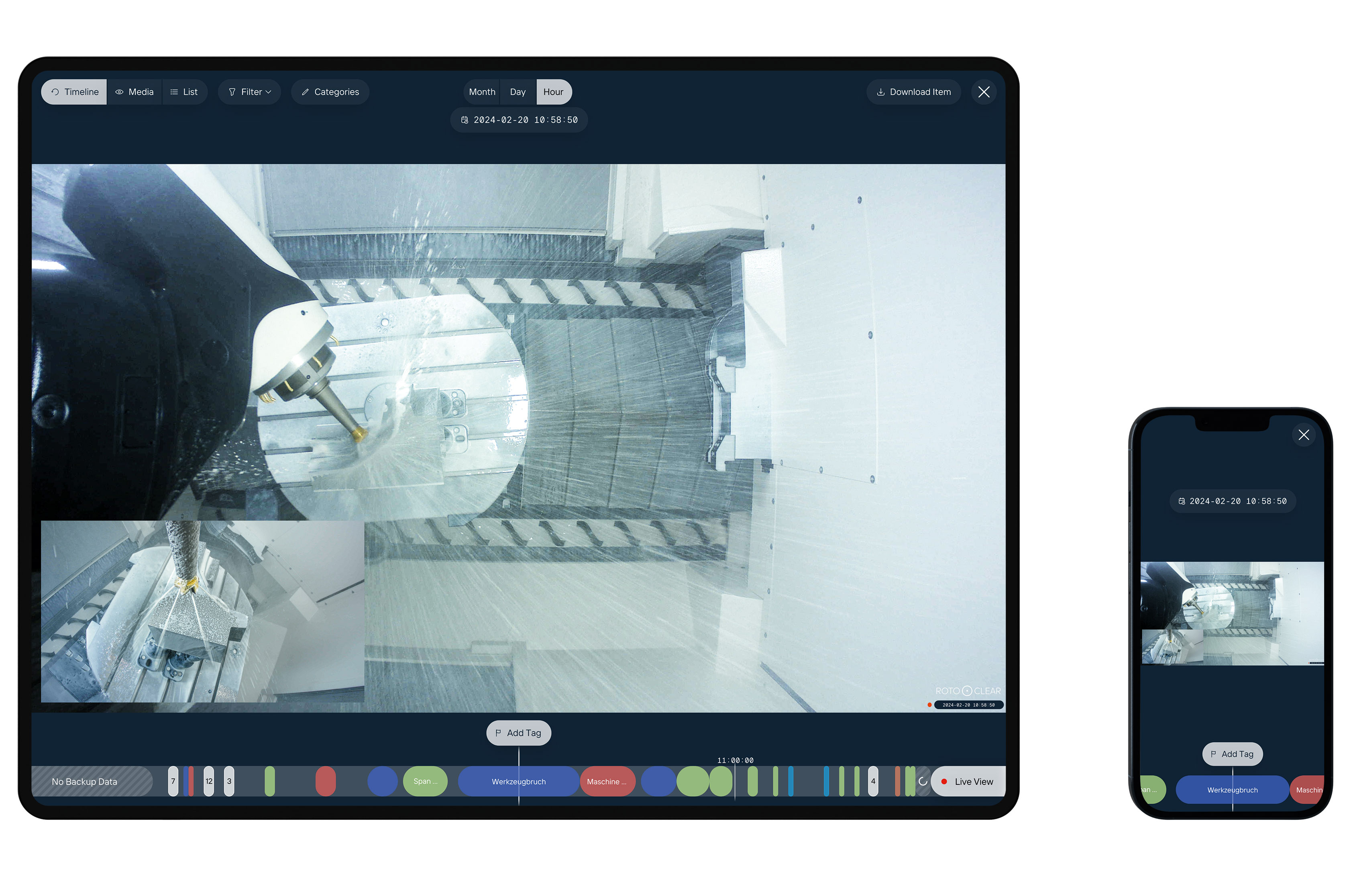

Via a web interface, some camera systems allow for remote control of manufacturing processes: employees do not always need to be on-site for process control but can gain insights into the machine tool from anywhere in the world. This can simplify work organization and save valuable resources.

Processing digital image data is key to further automating manufacturing processes: for example, chip nests could be automatically detected in the future, or warnings could appear if a tool shows excessive wear. An essential foundation for integrating the camera system into automated machine processes is that the camera system has an open API.

How camera systems

increase safety

Surfaces coated in greasy cooling lubricants – and sharp chips everywhere: every entry into the interior of a machine tool is associated with a safety risk. In the event that safety switches are negligently bypassed, opening the machine door can also pose great dangers to employees. With the help of camera systems, opening the machine door can be reduced to a minimum – thus significantly increasing safety for machine operators.

The development process

-

Development process of rotoclear camera systems

The first major step towards gaining insights into machine tools was spinning windows installed in the machine viewing pane. They allow machine operators an external view into the machine tool's interior.

The beginning: spinning windows

with an integrated camera

For the first time, a camera was integrated into such a spinning window: in 2016, the company Rotoclear presented a world first at the Metav trade fair in Düsseldorf with the Rotoclear vision: a Wi-Fi camera reliably provided users with insights into their machining, even remotely, for the first time.

A big step, but the perspective of the Rotoclear vision was, of course, still that of a machine operator – from the outside into the machine interior. Could one or even multiple cameras also be placed at other locations inside the machine?

Massive developments for

new perspectives

This question never left the minds of the product developers at Rotoclear. They designed cameras that could withstand the adverse conditions within a machine tool – and considered how the cameras could be optimally controlled and positioned inside the machine. They designed, built prototypes, and, together with renowned OEMs, put them through their paces.

In 2019, the time had come: with the Rotoclear C, the young company presented its first camera system at the EMO trade fair in Hanover, offering the viewer entirely new insights into machining processes – and from multiple perspectives simultaneously! The market reacted enthusiastically. Soon after, the first machine manufacturers began installing the system in their latest machine tools.

Tool itself gets eyes

Within a year, the camera system was consistently developed further – and already in 2020, the Rotoclear C2, the leading international camera system for machine interiors, was launched on the market.

The sensation? The new camera system made it possible, for the first time, to observe the machining process from the perspective of the tool itself, as the camera could be installed in the spindle head by the OEM.

The control unit of the Rotoclear C2 allows, among other things, for cameras to be controlled via a user interface, remote access to camera images, and manual saving of recordings.

The essence in real time

For users who can do without these additional functions and only require one perspective, the product family was expanded in 2021 to include a simple HDMI-based camera system: the Rotoclear C Basic. It provides users with high-resolution insights in real time via an HDMI monitor.

In the following years, the Rotoclear team consistently continued to develop the successful product range, including new software, a completely revised user interface, and further hardware optimization.

Latest generation of camera monitoring

In 2024, the time had come: The Rotoclear C Pro expands the existing features of the C-series with a new, practical function: the automatic Visual Backup and the ability to specifically analyze special moments in retrospect make it a comprehensive video monitoring system for manufacturing processes. Furthermore, the Rotoclear C Pro forms the foundation for the further automation of manufacturing monitoring, e.g., through AI-controlled evaluation of image data.

The outlook

-

Outlook: How camera systems will change the machining process

Intelligence needs data: this is why reliable optical information is essential for the further automation of process control and thus for the further optimization of manufacturing processes.

Automatic analysis of high-resolution

image data

Image data can be used for a wide variety of purposes, evaluated by artificial intelligence – and directly integrated into the machine control system via interfaces. This is no longer just a vision of the future: for example, the Institute of Manufacturing Technology and Machine Tools (IFW for short) is currently already using the Rotoclear C2 to recognize and analyze the formation of chips and chip nests on an AI basis.

"Our team has plenty of ideas for exciting solutions in the pipeline. Digital image data gives us completely new possibilities with which we will revolutionize manufacturing control."

David Jäckle,

Head of Software Development, Rotoclear

It can be assumed that a wide variety of software applications will become available here in the near future. With the introduction of the Rotoclear C Pro, for example, Rotoclear itself is working intensively on new AI tools with which the system can be expanded on the software side.

Furthermore, many customers in the manufacturing industry are also developing their own tools tailored to their individual requirements to further automate and optimize the control of their manufacturing processes.

The future? digital eyes +

artificial intelligence

An example? If the system detects that a tool cutting edge is worn, the machine can in the future automatically issue a warning to prompt a tool change. Just another example of the countless possibilities that arise when you give your machine tool digital eyes.

Do you have your own ideas for intelligent automation of process monitoring? Let's talk about it!

Manuel Linnenschmidt

Manuel is a Product Design Engineer at Rotoclear and thus responsible for the (further) development of Rotoclear windows and camera systems.

He is not only bursting with ideas but also always strives for products to inspire through innovative functions and ease of use. In our magazine, he reports on product developments, new features, and their practical application.