The Rotoclear C2 is for anyone looking to take optical process monitoring to the next level. This camera system allows you to observe machining processes from two perspectives simultaneously, providing even more valuable insights into your machining operations.

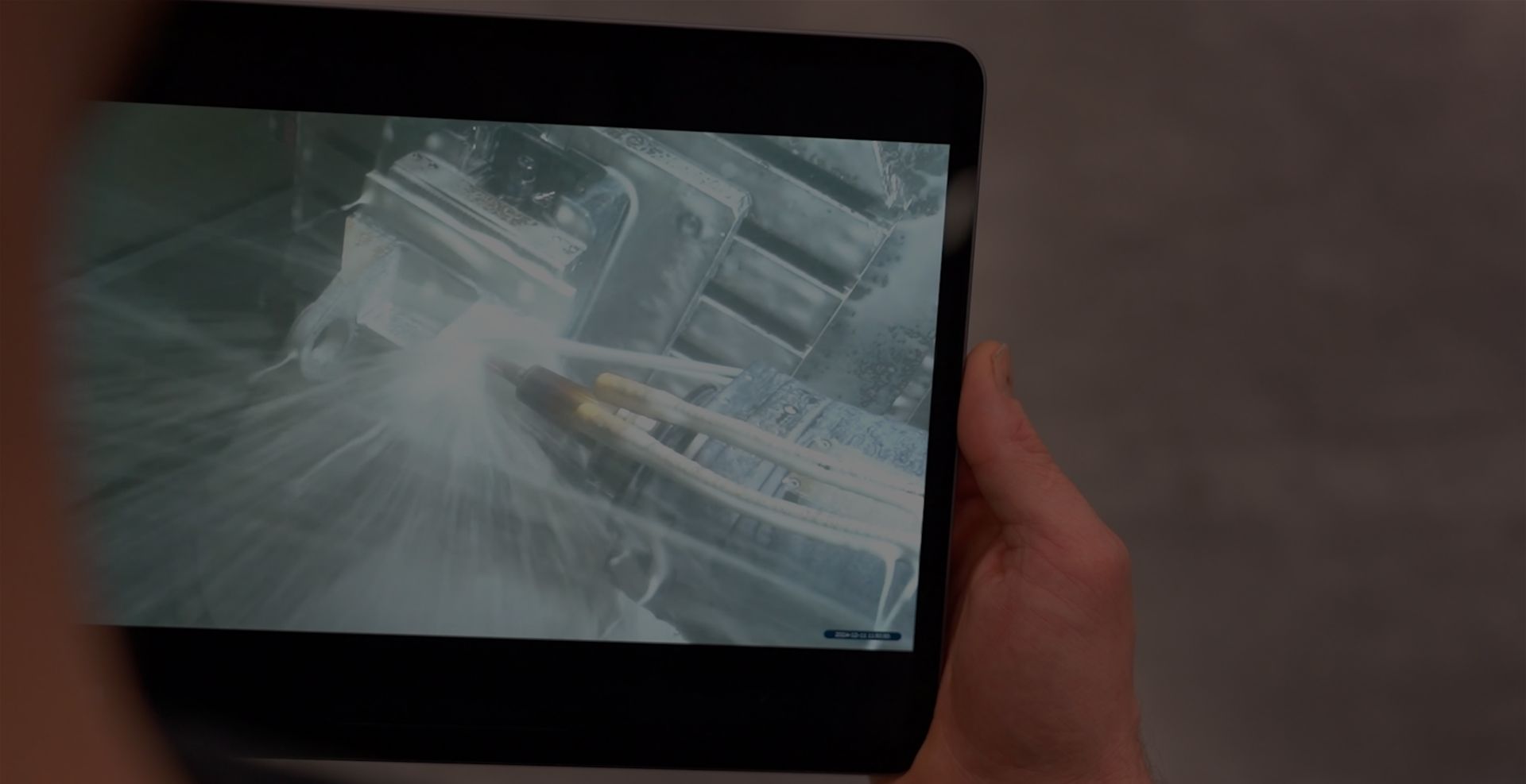

Watch your processes from anywhere!

Because the Rotoclear C2 control unit supports network streaming, you can monitor your machining processes remotely from any location in the world.

Your foundation for a professional production control center

Operating multiple machines from a centralized production control station is effortless with the Rotoclear C2. This makes it easier and more efficient to manage your process monitoring.

Five benefits of the

Rotoclear C2

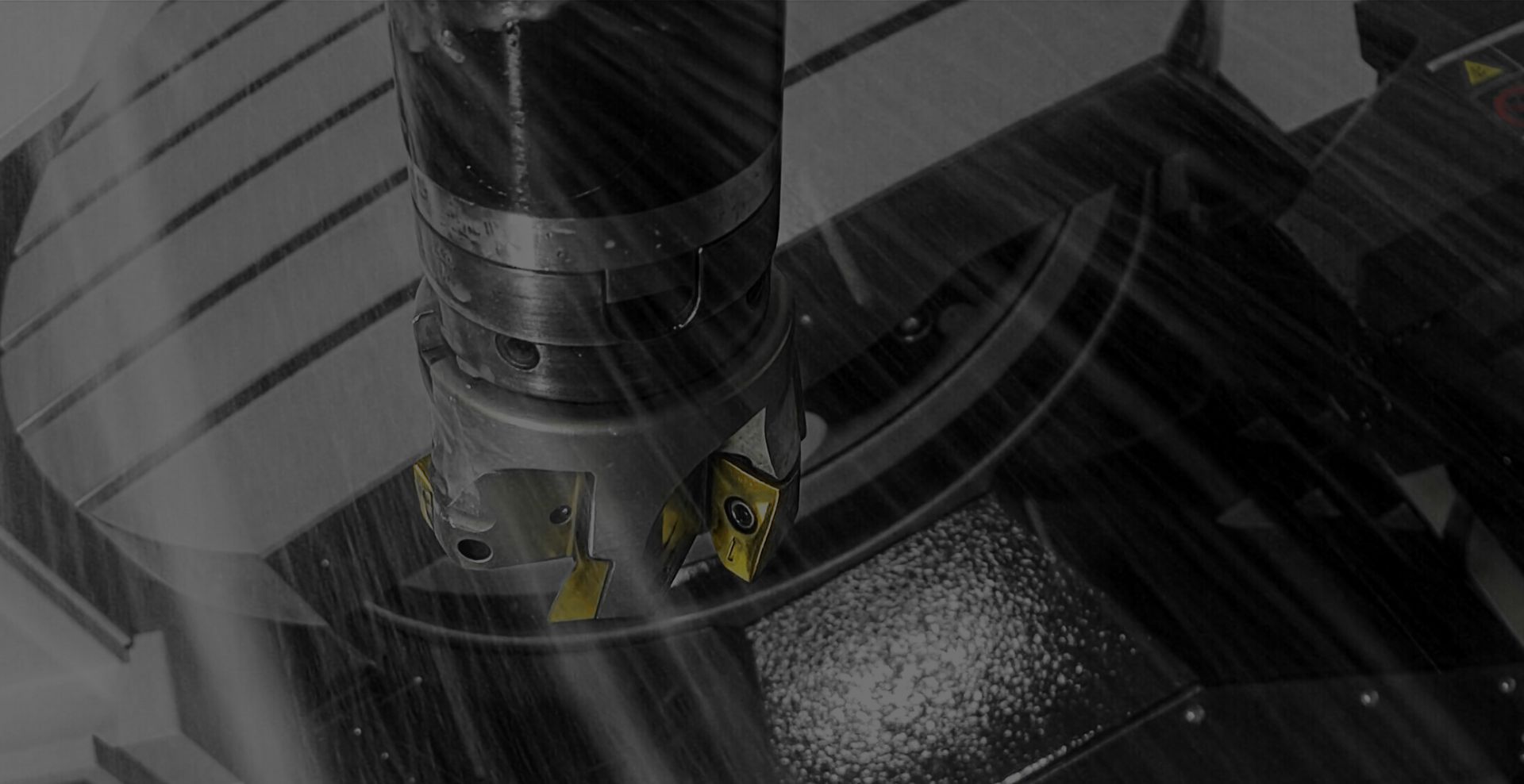

Always clear view

Specific use cases:

- Insights into enclosed systems

- Process monitoring despite the use of coolants

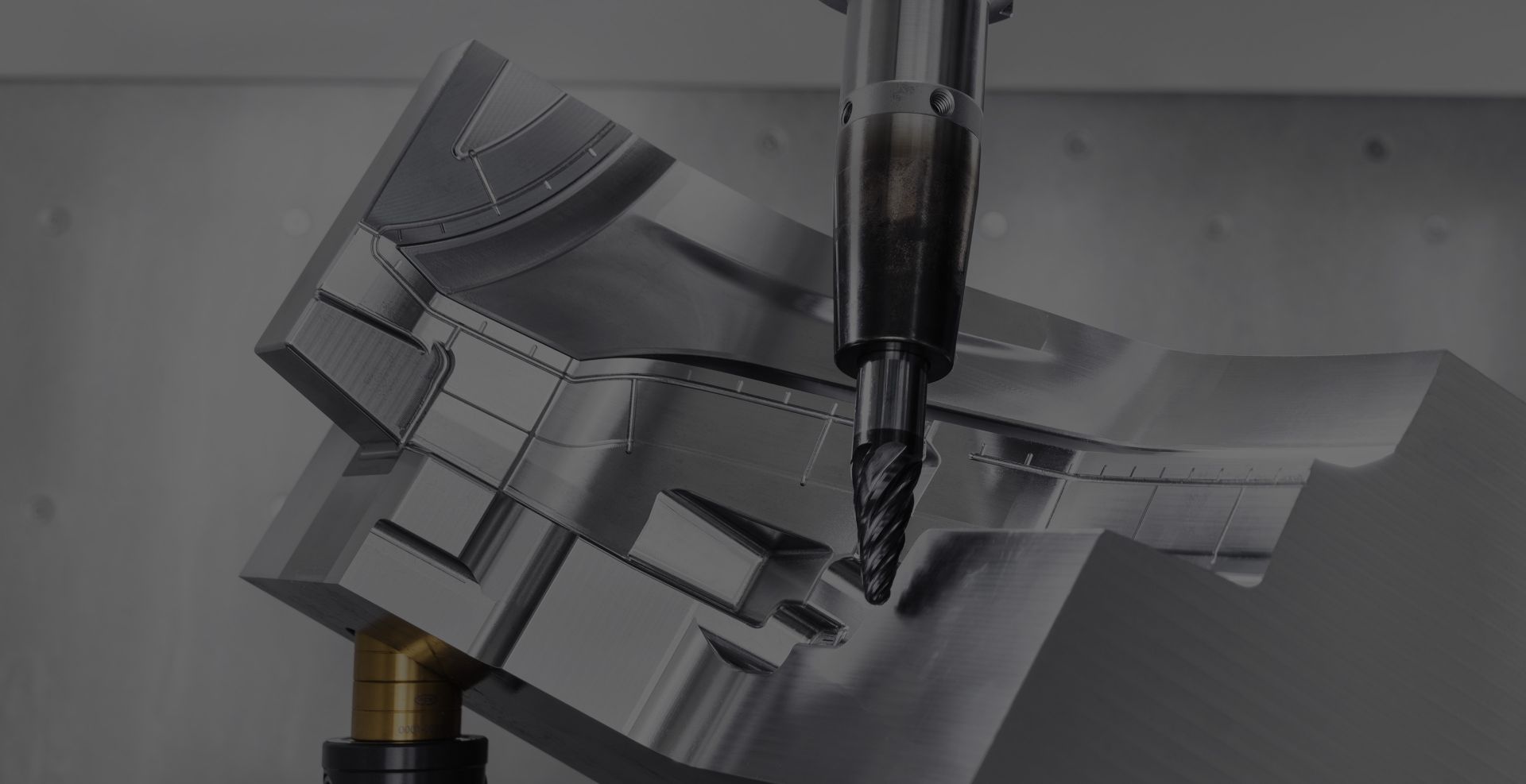

Observe processes from new perspectives

With the Rotoclear C2, you can monitor your machining processes from up to two perspectives simultaneously, providing surprising new insights!

Specific use cases:

- Observe machining processes in deep cavities

- Get close-up views in large machines

Streamline your process monitoring

The system also supports multi-machine operation — for example, via a production control station where you can view several machines at once and monitor processes on one or multiple screens via the ONVIF interface.

Specific use cases:

- Multi-machine operation (also for older machines)

- Avoiding time-consuming inspection rounds

- Increased flexibility for easier shift planning

Share your machining processes

the Rotoclear C2 lets you stream live processes or share recorded footage with colleagues.

Specific use cases:

- -

- -

- -

- -

Gain new insights for your process optimization

Specific use cases:

- Optimize setup and run-in processes by reducing non-productive time such as idle travel and positioning movements – maximizing valuable cutting time and overall machine productivity.

- Identify chip nest formation at an early stage and prevent it proactively by dynamically adjusting cutting parameters, ensuring stable and reliable machining processes.

Typical applications of the Rotoclear C2

Prototyping

Small to medium batch sizes

Monitoring start-up processes (ideal together with Rotoclear S3)

Manually capturing specific process steps

Centralized process monitoring

Training/academies, etc.

Communication of process expertise

Features of the Rotoclear C2

Always a clear view thanks to rotating disc

Our camera heads are specially designed for CNC machines: the fast-spinning disc in front of the lens ensures a clear view of all machining processes, even when using coolant or dealing with flying chips.

Up to two perspectives at once

Want to observe your manufacturing process from two perspectives simultaneously? No problem. By connecting two camera heads to the control unit, you can, for example, monitor machining both from above and from the tool’s perspective at the same time.

Free choice of perspective(s)

The Rotoclear C2 cameras can be mounted on the ceiling (Top View), on the side (Side View) of the workspace, or directly on the spindle (Tool View) — giving you clear insights from revolutionary perspectives.

Network streaming

With network streaming, you can access your image data remotely at any time. The Rotoclear C2 not only enables remote analysis, but also makes process monitoring more flexible.

Manual recording

By connecting external storage to the control unit, you can manually record specific process steps — for detailed analysis later or to share as documentation with customers or partners.

Swipe-Zoom

Want to zoom in on a section of the image? Simply swipe directly on the screen. Users can intuitively and quickly examine and analyze details of the machining process.

High resolution for sharp images

Our camera heads deliver up to 4K resolution at 60 frames per second in live streaming (manual recordings in HD or FullHD). Images can also be transmitted at lower resolutions or frame rates, such as FullHD — still producing sharp images even when zoomed.

Perfect illumination

Excellent images require perfect lighting conditions: that's why we have installed premium light sources from Waldmann in our camera heads, specially developed for this application.

Alignment sensor for movable installation

Only Rotoclear camera systems let you capture footage directly from the perspective of the cutting tool. To make this revolutionary view possible, we’ve integrated a position sensor. It detects the movement of the camera head and compensates for it in real time.

Choice of connectivity options

Whether HDMI, USB, or Ethernet, the Rotoclear C2 control unit provides all common connection options for fast, reliable image transfer — or to integrate the system into your own network.

Flexible mounting options

No matter where you want to place your camera(s): with numerous options for quick and easy mounting —whether through-wall, pre-wall, or on the ceiling—to create a customized and optimized camera setup.

Extended range for large machines

With our C-Extender signal amplifier, the Rotoclear C2’s range can easily be extended from 20 m to 40 m in large machines. Using two C-Extenders, distances of up to 60 m are even possible!

API interface

Want to implement new, machine-specific camera functions? No problem. Our API interface gives you full control — you can operate the camera directly from your software or automatically integrate image data into your workflow.

Rotoclear C Basic, C2 and C Pro side by side

Would you like to have all processes automatically recorded for later review? Or perhaps just get live insights into your machine from a single perspective?

If so, the Rotoclear C Pro or C Basic might be the right solution for you. We’ve summarized the key differences for easy comparison.

All-in-one system for easy setup

The Rotoclear C2 comes with everything you need to get your camera monitoring system up and running in no time: along with the camera head and control unit, all necessary cables, connectors, and mounts are included. You define the exact configuration yourself.

Find your perfect perspective!

With our camera systems, you can observe machining details up close — or monitor the entire machine interior. If desired, you can watch processes from two perspectives simultaneously.

From the tool's perspective: : Tool View

Want to observe the machining process up close? Rotoclear camera systems are designed so that a camera head can be mounted directly on the spindle housing, right by the tool holder. In most cases, however, this should be taken into account already during the machine’s configuration.

View from above: Top View

The top-down perspective from the machine ceiling gives operators a full view of the entire workspace. This helps them stay oriented, since they can see not only the overall process but also reference points and automation components at a glance.

View from the side: Side View

The Side View can be useful in many situations. It allows operators to keep a close eye on tool changes at all times. And when installing a Tool View isn’t possible, the Side View provides an excellent alternative for monitoring machining processes.

How to configure your Rotoclear C2

The Rotoclear C2 is suitable for a wide variety of machine types and applications. Depending on the size of your machine and the desired camera position, we offer system setups with different configuration options.

Use the online configurator to easily put together your individual system. You’ll then receive a tailored quote for your setup instantly.

What can you configure?

For different applications, you can choose between camera heads with varying depth-of-field ranges:

- F1: Close-range focus (200–500 mm — camera positioned near the tool)

- F2: Long-range focus (500–6000 mm — camera mounted on ceiling or wall)

- F1 + F2: Camera head allowing selection between F1 and F2

Our data cables are available in two lengths. If needed, you can extend them up to 60 m using a signal amplifier (C-Extender).

- 10 m (standard)

- 20 m

- 40 m = 20 m + 20 m → C-Extender required

- 60 m = 3 x 20 m → 2 x C-Extender required

No matter the design of your machine or where you want to mount the cameras, we have the optimal solution for you:

- The ball mount houses the camera and can be installed directly on the machine wall. The advantage? Its minimized profile reduces the risk of chip accumulation.

Learn more about the ball mount - Our flex-arm mount offers maximum flexibility in angle and perspective. It is available for through-wall mounting, pre-wall mounting, or with a magnetic mount.

Learn more about the flex-arm mount

Installation Dimensions

- The Rotoclear C2 camera unit measures Ø 70 mm × 50 mm

- The control unit measures 197 × 44 × 104 mm

- Its compact design allows installation even in tight spaces

All downloads for Rotoclear C2

Looking for detailed information, tips for optimal operation, or ways to maximize service life? Here you’ll find everything available for free download.

Rotoclear C2 Operating Manual

(PDF, max. 7 MB)

German | English

Rotoclear C2 Security Analysis

(PDF, max. 200 KB)

German | English

Rotoclear C2 Software

(.fw-file, approx. 40 MB)

Latest version | Changelog

Accessories or spare parts for the Rotoclear C2? Find and order now.

Need accessories or spare parts for the Rotoclear C2? Our configurator helps you quickly find exactly what you need — and order it directly. Everything will be delivered to you in no time!